Utilizing Magnetic Force, “Magno” Gearbox, for the Development of Indonesian Machinery Program

As the central component of the drive system, the gearbox converts the low speed of the rotor shaft into a high revolution that drives the generator. The transmission box which is also known as the gear box is the second element of the power train in an automobile. It is used to change the speed and torque of vehicle according to variety of road and load condition. Gearbox is a component used in various machines, one of the machines that use this tool as the main component is windmill. A windmill is a mill that converts the energy of wind into rotational energy by means of vanes called sails or blades. These blades are connected to a generator, sometimes through a gearbox

A group of students of Department of Mechanical and Biosystem Engineering of the Faculty of Agricultural Technology of Bogor Agricultural University (FATETA IPB) made innovation on the application of magnet force on gearbox. Under the sponsorships of Kelompok Program Kreativitas Mahasiswa bidang Karsa Cipta (PKM-KC Student Creativity Program for Karsa Cipta). The group consists of Farras Aryo Bramasta, Aqil Bramasta, Maulana Syafiq K, Siaga Yudha Pratama, and M Nyak Reza Mahbub. They planned to apply the gearbox technology for the windmills with the aim of generating electrical power from the rotation motion of the mill.

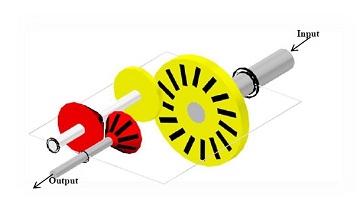

The gearbox, they named “Magno”, is a transmission system that utilizes magnetic forces to generate electrical power from the rotation of the disc on the windmill. The 52nd Neodymium magnetic bar is arranged into discs and makes it a gearbox substitute for a conventional gearbox. There are two axes of discs in this tool, including the input shaft, and the output shaft. Each of them serves as funnel different power.

The team used the highest grade of neodymium magnet N52 type. This magnet was chosen because of its highest strength among other common magnets on the market. A neodymium disc magnet weighing only 2 grams can lift a steel block weighing over 2,000 grams.

"No physical touch between magnetic force with the other components, PKM-KC team applied magnets into the gearbox so that the dental disc has more rotation and no friction," said Aryo as the team leader.

“Magno” gearbox had been manufacted in Bogor, until now the process of undertaking the prototype is still going on. The main material of Magno gearbox is nylon. In fact, nylon rope is a great choice for any tie-down because of its strength. The windmill that is functioning as the gearbox test equipment of “Magno” also designed by the team as a test tool. The dimensions of “Magno” is approximately 20 cm cubic in volume.“Magno” is designed to have such a positive impact on machinery as well as the environment compared to the conventional Gearbox. Gearbox application usage is very diverse as in the needs of machinery, mining, and others. Gearboxes in these areas are used to strengthen the power of the main engine. Gearboxes are used widespread across a range of industries due to the numerous benefits they provide. The term is also applied to some gearboxes used on the shipping, it is used to support for raising or lowering anchors. (Wied)